'

Once wet concrete starts to pour, you need to be prepared to move quickly. No one wants to get to the job site and realize they left a tool behind. Here’s a list of 30 tools you might need on a concrete construction site from start to finish:

Pouring Cement

- Mixers

Um, naturally, right? But whether you’re mixing in a truck, a portable mixer or a wheelbarrow, you want to be sure your concrete is thoroughly mixed for maximum strength and durability. - Wheelbarrows

Ideal for transporting (or even mixing) small batches of concrete or tools on the job site. - Rubber Boots or Work Boots

Concrete is stiff stuff, and wearing waterproof boots is the best way to get through it and prevent contact with your skin. It’s also easy to rinse your footwear after the concrete is down. - Gloves

Many concrete mixes contain potentially caustic admixtures that can cause serious burns from extended contact with bare skin. Gloves prevent overexposure to these components (and save a few occasional blisters, too). - Safety Glasses

Standard on most job sites, wearing safety glasses is an important safety measure when drilling, grinding, power trowelling or sawing concrete. - Compactors

If the site of the concrete slab is to be prepped with a sub base of any type, a compactor helps settle the stone or aggregate into position. - Levels

Both the sub base and slab surface must be level. A standard long-line level, or a laser level, will let you verify that the slab is completely according to spec before pouring and after. - Tape Measures

Concrete forms and slab depth need the same “measure twice, pour once” verification as any other material on the job site. They are also useful for testing placement and mapping. - Moisture Retarders

Moisture or vapor retarders are used to prevent water vapor from intruding on a finished concrete slab. They are generally placed directly under on grade or below grade slabs. - Saws

Reciprocating saws, circular saws or grinders can be necessary to cut rebar or forms on the job site. They can also be necessary if a problem develops under the slab and a portion of the concrete has to be removed after it has set and dried. - Shovels

Shovels help distribute concrete around the job site to fill in gaps left during the pouring process or for smaller applications. Square-ended shovels generally work better for concrete; rounded ones spread concrete unevenly. - Rakes and Come-Along Rakes

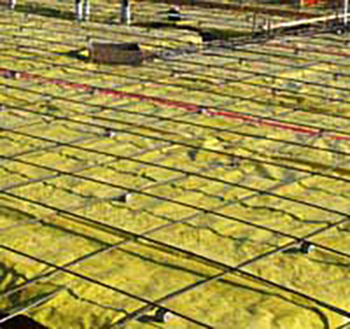

Using a rake is the quickest way to begin getting the freshly-poured concrete spread more uniformly into place. Garden rakes work but concrete rakes, also called come-along rakes, have a more scooped blade for more easily pre-leveling new concrete. Concrete rakes also have a tine on the back of the blade to help lift rebar or mesh into position before the concrete begins to harden. - Tampers

A tamper is used with low slump concrete to push the aggregate below the slab surface. There are types that are used standing on the wet concrete, or roller types that can be used from the slab edge. - Vibrators

Concrete vibrators help release trapped air pockets and excess water from the concrete mix to prevent possibly compromising problems in medium to high slump concrete. - Screeds

Screeds come in a variety of sizes and can be a specific tool (also called straight edges or bump cutters), or can be simple flat pieces of dimensional lumber. The purpose of a screed is to smooth concrete after it has been moved into place by scraping away any excess from the slab surface. - Bull Floats

Bull floats are wide-bladed tools on a long (possibly telescoping handle) that provide the first pass for leveling ridges and filling voids in the concrete after the screed work has been done. - Magnesium Floats

Magnesium floats (or mag floats) are smaller handheld floats typically used to float slab edges or to use for finish work on smaller slabs. - Kneeling Boards

For hand troweling work especially, kneeling boards provide a smooth way to support your weight on the wet concrete while moving easily along the slab surface.

Finishing Concrete

Trowels

Trowels

Trowels also help smooth concrete surfaces for their finish coats before being left to dry. Hand-troweling is common for smaller slabs, or power trowels are often preferred for large slabs. There are varying types of trowels for specific concrete work.- Float Blades and Troweling Blades

A variety of blade types is available for floats and power trowels, each designed to accomplish different finishes. Some care must be taken during the troweling stage not to burnish the surface and prolong drying time. - Groove Cutter/Jointer Tool

For certain job types, grooving the surface also helps prevent cracking or excess damage from shrinkage as the concrete dries or during use. - Edger

An edger is a tool designed to round exposed concrete edges for a smooth finish. - Brooms

A traditional finish for a concrete slab is a broom finish – drawing a broom across the surface of the almost-dried concrete slab for a slip-resistant surface. The finished look can be a smooth draw or a more artistic pattern. - Polishers

After the slab has dried sufficiently, polishers can be used to produce a surface finish effect, from a gentle smoothing of the surface for traction and safety to a mirror-like shine for an aesthetic finish. - Grinders

Grinding can also be used for aesthetic effects like a distressed finish, or is also sometimes necessary if a slab surface has been over-trowelled and excess moisture is sealed inside the slab. - Dust Collection Systems

When grinding, polishing, drilling or sawing concrete, a dust collection system helps clear the work area and protect the health of the onsite workers.

Testing Concrete

Thermo-Hygrometers

Thermo-Hygrometers

Ambient conditions play a big role in determining drying time. A thermo-hygrometer helps monitor both temperature and relative humidity (RH) in the space around the concrete slab and inform potential remediation methods to speed drying time.- Hammer Drills or Rotary Drills

Placing concrete anchors or doing RH testing require drilling into a cured concrete slab. Hammer drills (or rotary drills) make the process easier by combining rotation with “percussion” – a pounding motion that breaks up the concrete faster for easier installation. And don’t forget the right bits for the job, too. - Concrete Moisture meters

Concrete moisture meters can provide handy “spot checks” of drying slabs. However, care must be taken to remember that they, like the hood method or the calcium chloride method, only provide an indication of surface conditions. - Relative Humidity (RH) Test Kit

For an accurate indication of the internal moisture condition of a drying slab, RH testing with in situ probes provides effective internal moisture measurement. Backed by ASTM F2170, RH testing can provide necessary moisture data for concrete and flooring installers alike and prevent possible moisture-related problems down the road.